Manufacturing and Analytical Characterization - Biomolecular

(W1130-11-65) Engineering Spray Dried Protein Particles to Enable Subcutaneous Injection of High Concentration Protein Suspensions

Quinn Rasmussen, BS

Scientist II

Serán Bioscience

Bend, Oregon, United States

Quinn Rasmussen, BS

Scientist II

Serán Bioscience

Bend, Oregon, United States

Cindy Chung, Ph.D. (she/her/hers)

Principal Engineer

Serán Bioscience

Bend, Oregon, United States- MC

Mary Collins, Ph.D.

Senior Scientist

Serán Bioscience

Bend, Oregon, United States .jpg)

Tanner J. Corrado, PhD

Senior Scientist

Serán Bioscience

Bend, Oregon, United States- NR

Nick Rasulo, BS

Engineer II

Serán Bioscience

Bend, Oregon, United States - SP

Sarah Peabody, BS

Intern

Serán Bioscience

Bend, Oregon, United States - BS

Brian Smith, MS

Engineer I

Serán Bioscience

Bend, Oregon, United States - GD

Gabriella Dube, BS

Engineer I

Serán Bioscience

Bend, Oregon, United States - MK

Mark Kastantin, Ph.D.

Vice President of Manufacturing Technology

Serán Bioscience

Bend, Oregon, United States

Erica Schlesinger, Ph.D. (she/her/hers)

Vice President of Technical Development

Serán Bioscience

Bend, Oregon, United States

Presenting Author(s)

Main Author(s)

Co-Author(s)

Methods: In this study, we look specifically at the relationship between droplet drying rate and the resultant particle properties that influence extrusion force of the resultant suspensions. Bovine serum albumin (BSA) is used as model protein with sucrose as the thermal stabilizer in the spray dried powder (SDP) formulations. Spray dried particles were manufactured on custom built spray dryers, and drying rates were varied by changing control parameters related to the spray drying process. The resultant throughput was calculated for a range of drying rates under different processing parameters to identify the bounds of the relevant design space. The resulting particles were analyzed by SEM as well as bulk and tapped density to determine the impact of drying rate on powder and particle properties that have previously been identified as key parameters impacting suspension viscosity. SDPs suspended at 40 wt% total solids in Miglyol 840 were dispensed through a BD Neopak 27G ½” STW glass syringe at a rate of 1 mL in 8 seconds using a Texture Analyzer to determine extrusion or dispensing force.

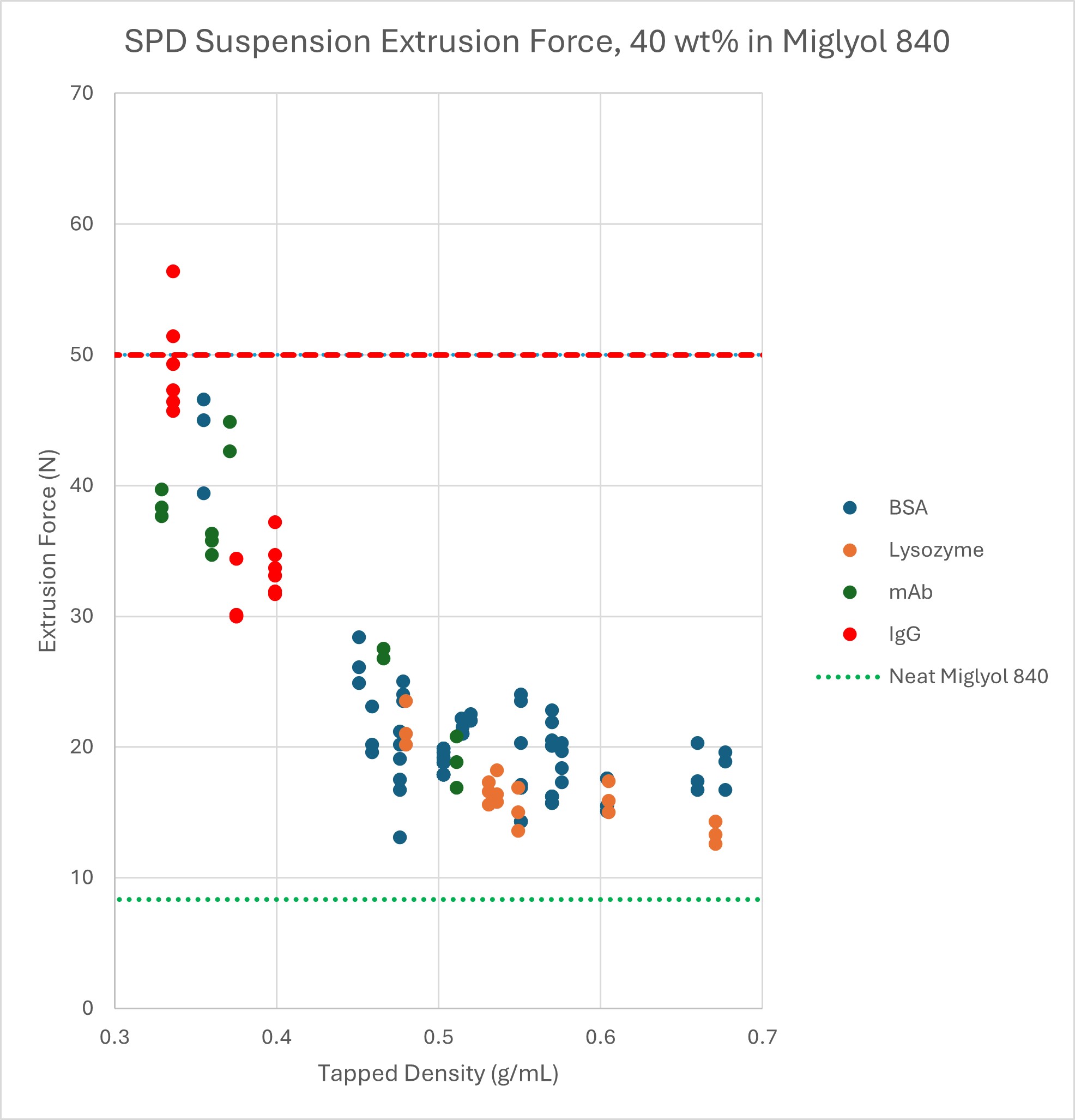

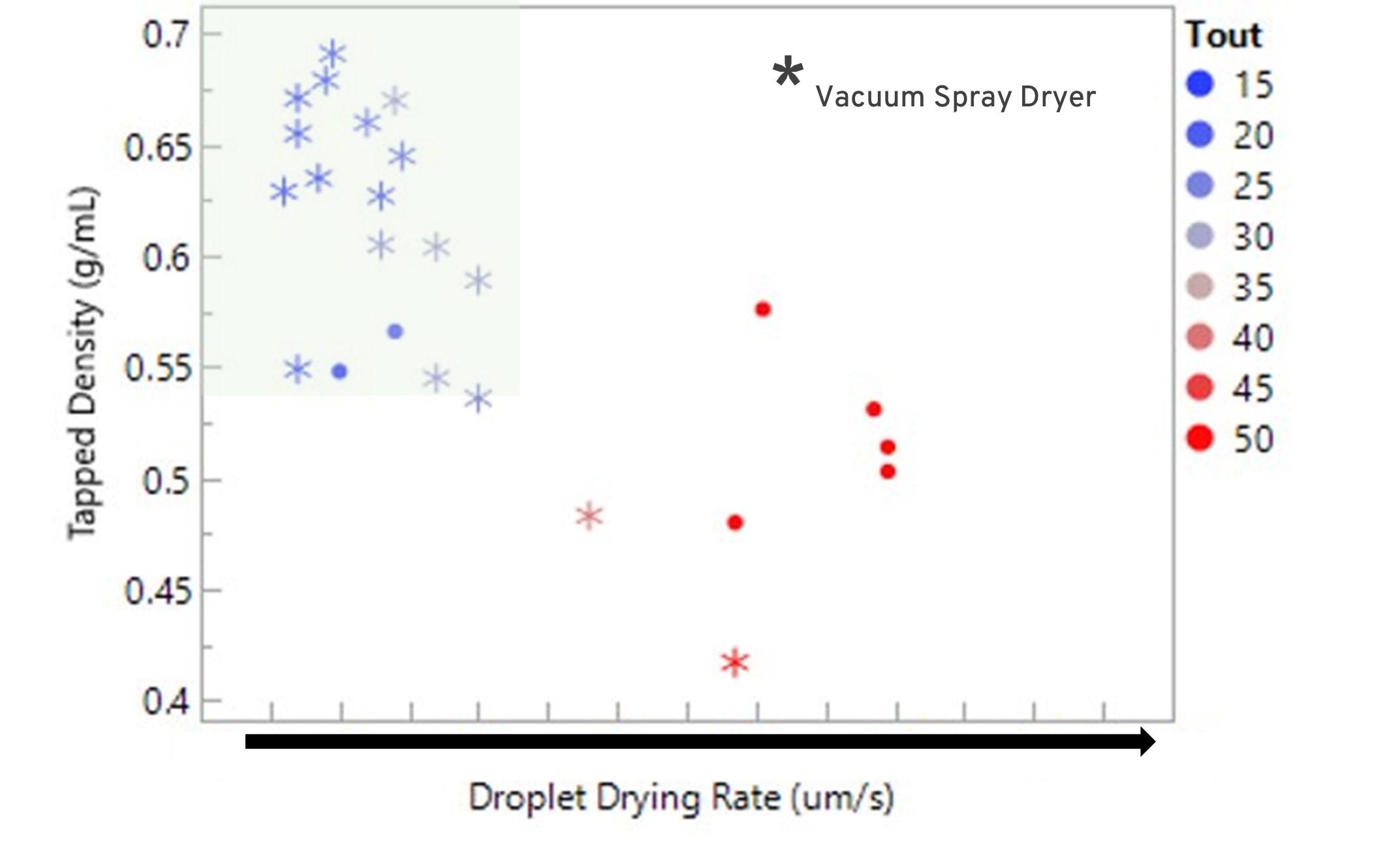

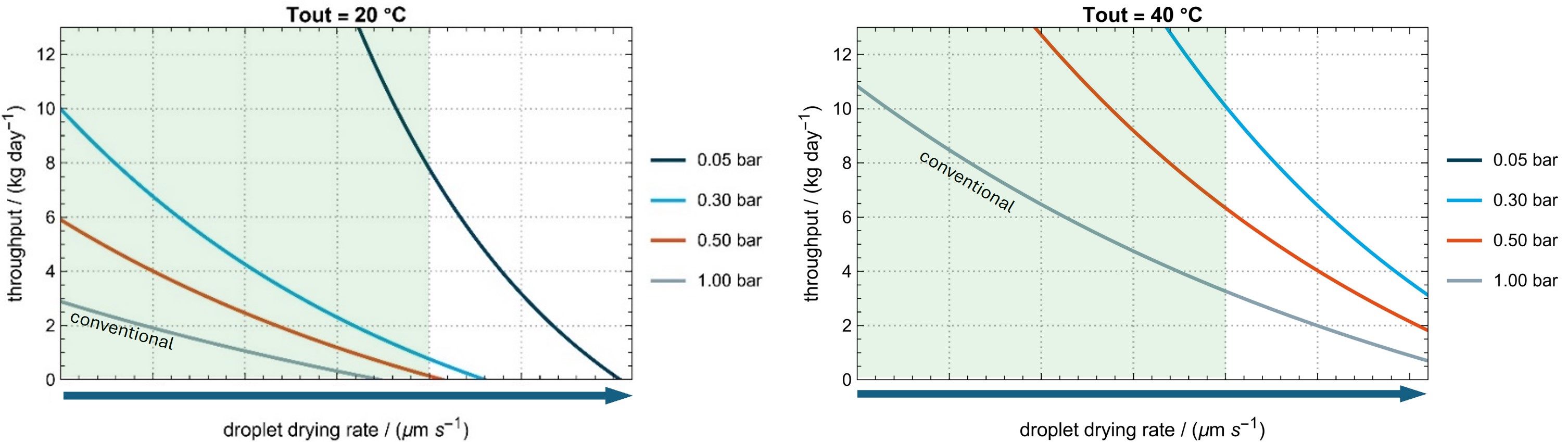

Results: We previously identified tapped density as a non-destructive measurement that correlates with suspension viscosity, where SDP with higher tapped densities resulted in lower suspension viscosities and thus lower extrusion forces. In this study, we demonstrate that droplet drying rate can be used to engineer SDP with higher tapped densities, leading to lower extrusion forces. We show that droplet drying rate is inversely correlated to the tapped density of the resultant SDP for a given formulation and that reduced dryer pressure allows increased throughput for a given drying rate and outlet temperature. By decreasing drying rate we can achieve higher tapped densities.

Conclusion: This study establishes a strategy for particle engineering via spray drying to produce high tapped density powders that enable high concentration subcutaneous injections of therapeutic proteins. In future work we plan to expand this data set to include more proteins and protein formulations.

Figure 1. Tapped density and extrusion force of the SDP particles prepared using four model proteins. Red, dashed line represents the maximum extrusion force (50 N) for the target product profile.

Figure 1. Tapped density and extrusion force of the SDP particles prepared using four model proteins. Red, dashed line represents the maximum extrusion force (50 N) for the target product profile. Figure 2. Drying rate and tapped density for SDP particles sprayed at different outlet temperatures. SDPs manufactured on a conventional spray dryer are denoted with a dot and those manufactured on a vacuum spray dryer are denoted with a star. The green box indicates the target design space.

Figure 2. Drying rate and tapped density for SDP particles sprayed at different outlet temperatures. SDPs manufactured on a conventional spray dryer are denoted with a dot and those manufactured on a vacuum spray dryer are denoted with a star. The green box indicates the target design space. Figure 3. Drying rate and throughput for SDP sprayed at varied dryer pressures with an outlet temperature of 20 °C (left) and 40 °C (right).

Figure 3. Drying rate and throughput for SDP sprayed at varied dryer pressures with an outlet temperature of 20 °C (left) and 40 °C (right).