Formulation and Delivery - Chemical

(M1130-05-29) Rapid Detection of Formulation Stability for Fast Product Development

Monday, October 21, 2024

11:30 AM - 12:30 PM MT

- CB

Connor Bilchak, Ph.D.

Scientist

BASF Corporation

Tarrytown, New York, United States - CB

Connor Bilchak, Ph.D.

Scientist

BASF Corporation

Tarrytown, New York, United States

Presenting Author(s)

Main Author(s)

Purpose: Stability testing of pharmaceutical topical creams is important for determining product shelf life. However, this is often a time- and labor-intensive process; while some accelerated aging protocols exist, this process can take weeks to months and relies on subjective visual identification of separation. Ideal testing methods would be fast (~hr), quantitative, and employ standard characterization equipment. Here, we present two rheological methods for qualitatively probing the stability of different cream formulations. The approach is to employ measurements of microstructure to develop stability criteria. This is accomplished by synergizing rheological measurements during thermal cycling and optical microscopy of samples exposed to a steady-shearing protocol.

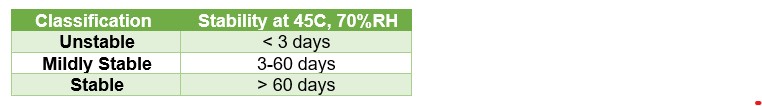

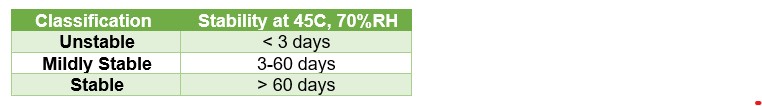

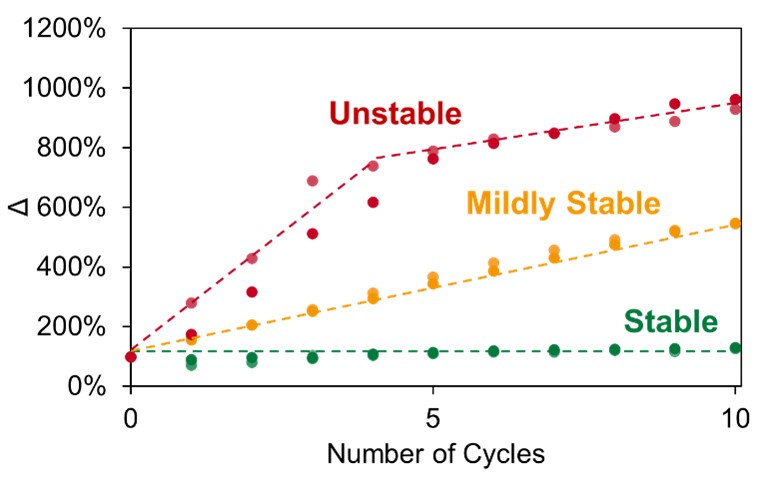

Methods: Seven creams of various known stabilities were formulated using the conventional direct hot processing method. Each is classified as ‘stable’, ‘mildly stable’, or ‘unstable’ based on the criteria should in Table I. The initial microstructures were characterized using optical microscopy. Cream stabilities were tested using two separate techniques. In the first, the product viscosity was measured during in-situ temperature cycling from 25C to 55C, at a rate of 10C/min, using oscillatory shear rheology. The overall microstructure change Δ from temperature cycling was calculated by dividing the maximum complex viscosity of each cycle by the initial value before temperature cycling. A Δ of 100% means that the cream viscosity, and therefore microstructure, is unchanged by the temperature cycling. Unstable creams are expected to show large Δ. In the second technique, a sample of each cream was controllably sheared in rotation at a rate of 500 s-1 for five minutes. The microstructure of the sheared sample was then observed using optical microscopy and compared to the pre-sheared microstructure. The results of both tests were compared with visual observations of samples aged in an environmental chamber at 40C and 75% relative humidity.

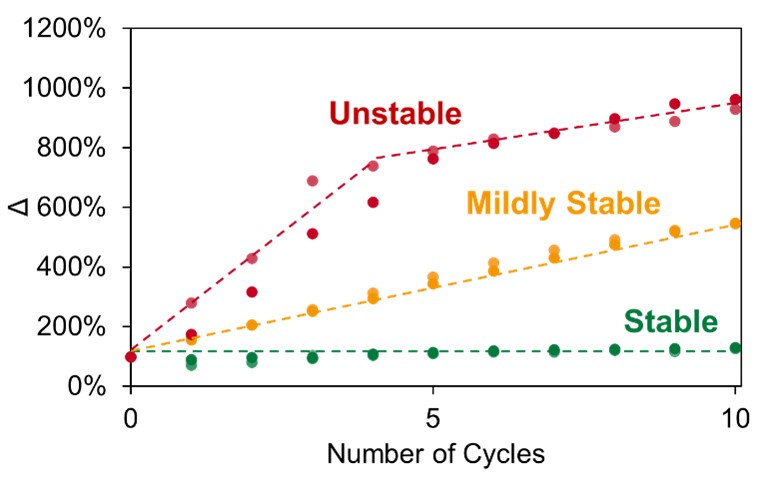

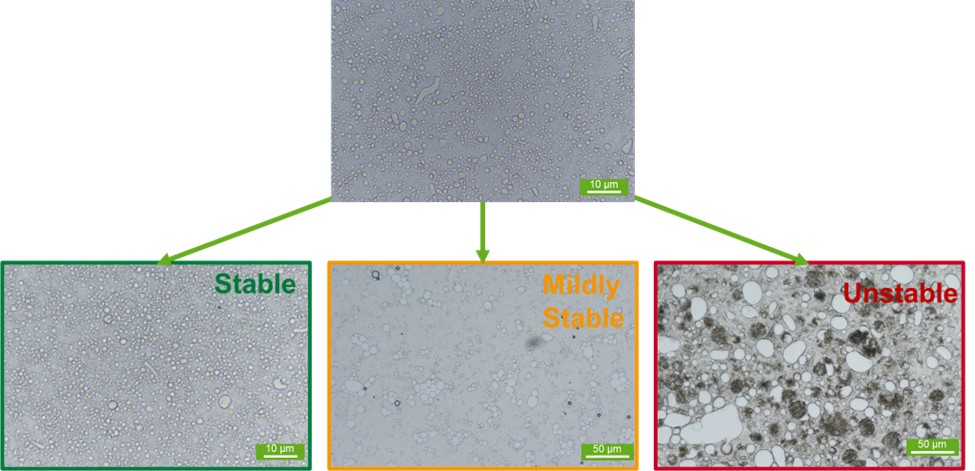

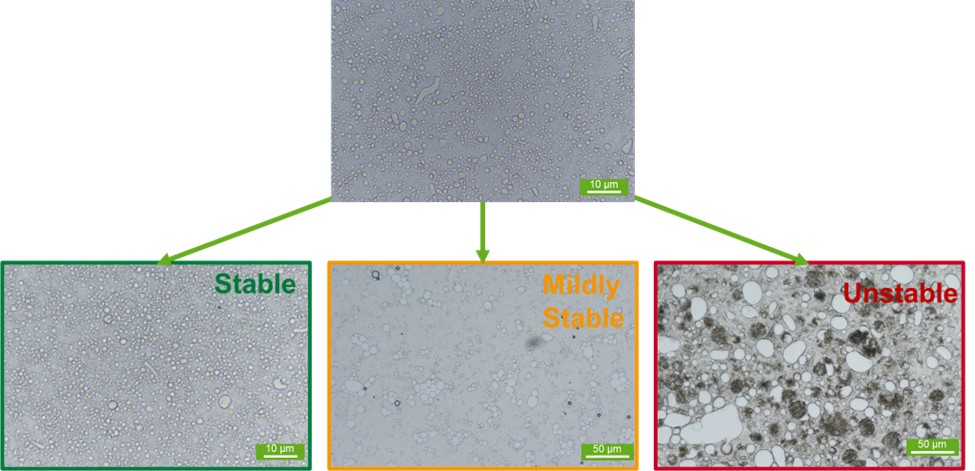

Results: The microstructure change of the creams generally followed one of three different trends, depending on their stabilities (Figure 1). All stable creams have gradual increases in Δ as the cycle number increases and remains < 130% after ten cycles, indicating a stable emulsion microstructure. The stable formulations also showed no visual signs of creaming after up to 2 months of accelerated aging; optical microscopy also showed minimal changes in emulsion microstructure, consistent with results from rheology testing. Unstable formulations show much larger changes in Δ, ranging from 400-700% after ten cycles. There are two different behaviors observed for the unstable formulations—in some, Δ increases linearly, with a single, constant slope. Others show a two-slope behavior, where Δ increases rapidly for early cycles and then more slowly for later ones. Creams showing the single-slope behavior were visibly unstable after 4-25 days of accelerated aging; creams with the two-slope behavior were visibly unstable after less than three days. Large changes in Δ are therefore generally indicative of unstable emulsions, with those showing two-slope behavior to be highly unstable. The stability of the creams can also be probed by observing the effect of shear on the emulsion microstructure; Figure 2 shows optical microscope images of three creams (one representing each stability category seen during temperature cycling) after shearing. The initial microstructures are similar, with discrete oil droplets ~2-5 um in diameter dispersed in the continuous phase. This structure remains post-shear for stable creams. However, the unstable ones again show two different behaviors. Mildly unstable cream microstructures show oil droplets with a slightly larger average diameter that have flocculated because of the shearing process. The oil droplets in the unstable cream have coalesced/crystallized post-shear.

Conclusion: Two methods for qualifying emulsion stabilities using common analytical testing equipment were introduced. Both methods reveal unique trends based on the emulsion stability—rheological measurements demonstrate early detection of morphological changes on temperature cycling, while subjecting emulsions to shear can show non-recoverable changes in droplet structure. The two methods can be easily modified to study the effects of various thermal and shearing conditions. Employing these two tests synergistically can allow formulators to identify and troubleshoot stability issues orders of magnitude faster, drastically reducing product development times.

Stability criteria for creams used in this study

Changes in cream microstructure (measured via viscosity change) during temperature cycling.

Cream microstructures pre-shearing (top) and post-shearing (bottom) are stability dependent

Methods: Seven creams of various known stabilities were formulated using the conventional direct hot processing method. Each is classified as ‘stable’, ‘mildly stable’, or ‘unstable’ based on the criteria should in Table I. The initial microstructures were characterized using optical microscopy. Cream stabilities were tested using two separate techniques. In the first, the product viscosity was measured during in-situ temperature cycling from 25C to 55C, at a rate of 10C/min, using oscillatory shear rheology. The overall microstructure change Δ from temperature cycling was calculated by dividing the maximum complex viscosity of each cycle by the initial value before temperature cycling. A Δ of 100% means that the cream viscosity, and therefore microstructure, is unchanged by the temperature cycling. Unstable creams are expected to show large Δ. In the second technique, a sample of each cream was controllably sheared in rotation at a rate of 500 s-1 for five minutes. The microstructure of the sheared sample was then observed using optical microscopy and compared to the pre-sheared microstructure. The results of both tests were compared with visual observations of samples aged in an environmental chamber at 40C and 75% relative humidity.

Results: The microstructure change of the creams generally followed one of three different trends, depending on their stabilities (Figure 1). All stable creams have gradual increases in Δ as the cycle number increases and remains < 130% after ten cycles, indicating a stable emulsion microstructure. The stable formulations also showed no visual signs of creaming after up to 2 months of accelerated aging; optical microscopy also showed minimal changes in emulsion microstructure, consistent with results from rheology testing. Unstable formulations show much larger changes in Δ, ranging from 400-700% after ten cycles. There are two different behaviors observed for the unstable formulations—in some, Δ increases linearly, with a single, constant slope. Others show a two-slope behavior, where Δ increases rapidly for early cycles and then more slowly for later ones. Creams showing the single-slope behavior were visibly unstable after 4-25 days of accelerated aging; creams with the two-slope behavior were visibly unstable after less than three days. Large changes in Δ are therefore generally indicative of unstable emulsions, with those showing two-slope behavior to be highly unstable. The stability of the creams can also be probed by observing the effect of shear on the emulsion microstructure; Figure 2 shows optical microscope images of three creams (one representing each stability category seen during temperature cycling) after shearing. The initial microstructures are similar, with discrete oil droplets ~2-5 um in diameter dispersed in the continuous phase. This structure remains post-shear for stable creams. However, the unstable ones again show two different behaviors. Mildly unstable cream microstructures show oil droplets with a slightly larger average diameter that have flocculated because of the shearing process. The oil droplets in the unstable cream have coalesced/crystallized post-shear.

Conclusion: Two methods for qualifying emulsion stabilities using common analytical testing equipment were introduced. Both methods reveal unique trends based on the emulsion stability—rheological measurements demonstrate early detection of morphological changes on temperature cycling, while subjecting emulsions to shear can show non-recoverable changes in droplet structure. The two methods can be easily modified to study the effects of various thermal and shearing conditions. Employing these two tests synergistically can allow formulators to identify and troubleshoot stability issues orders of magnitude faster, drastically reducing product development times.

Stability criteria for creams used in this study

Changes in cream microstructure (measured via viscosity change) during temperature cycling.

Cream microstructures pre-shearing (top) and post-shearing (bottom) are stability dependent